Providing important advantages and distinguishing ourselves from the competition

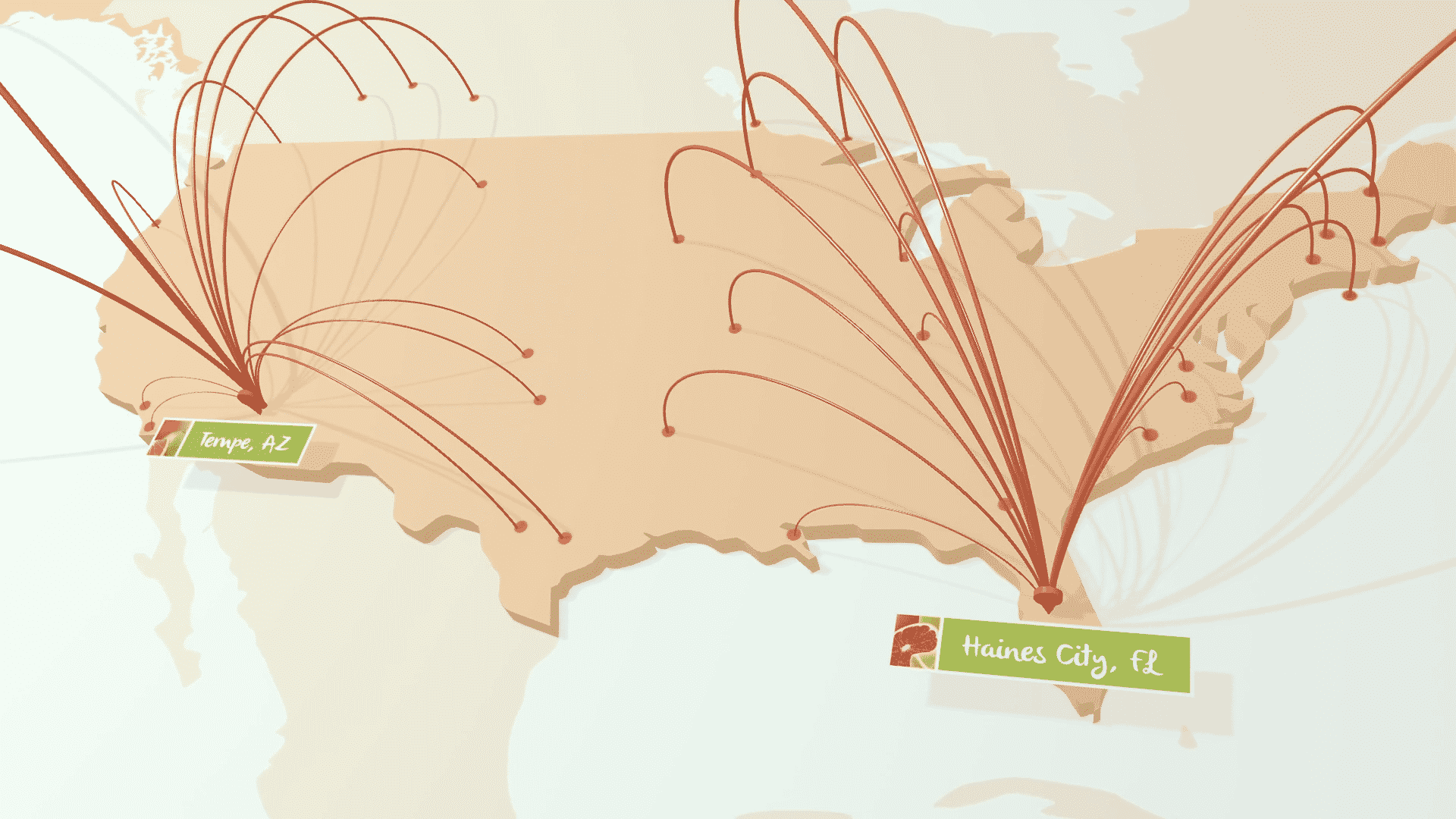

Manufacturing

- Bi-coastal manufacturing facilities able to produce 30 million gallons annually

- Supply chain efficiencies

- Continuity of supply; risk mitigation

- Capacity planning and operational expertise

Manufacturing Facility, Haines City, Florida

Manufacturing Facility, Tempe, Arizona

Distribution

- Multiple ship points that handle over 5.5M cases annually

- Over 90,000 square feet of refrigerated and frozen warehousing space

- Weekly FTL and LTL shipments to every major market

- Best-in-class inbound and outbound inventory management processes

- Cross-dock options and pick up program

Distribution Center, Haines City, Florida

Distribution Center, Tempe, Arizona